Und. Research Project

At Tsutsumi Asakichi Urushi Inc., we expand the possibilities of Urushi by collaborating with experts from various fields, including designers, artists, and researchers, to explore new materials and technologies through research and experimentation. The projects born here are developed as future tools for Urushi craftsmen and daily living, to make them widely available in the market in diverse forms.

Rules

- Make use of existing resources.

- Create systems for long-term and meaningful use.

- Collaborate with diverse people, materials, cultures, and technologies.

Urushi × PLA × 3D Printer

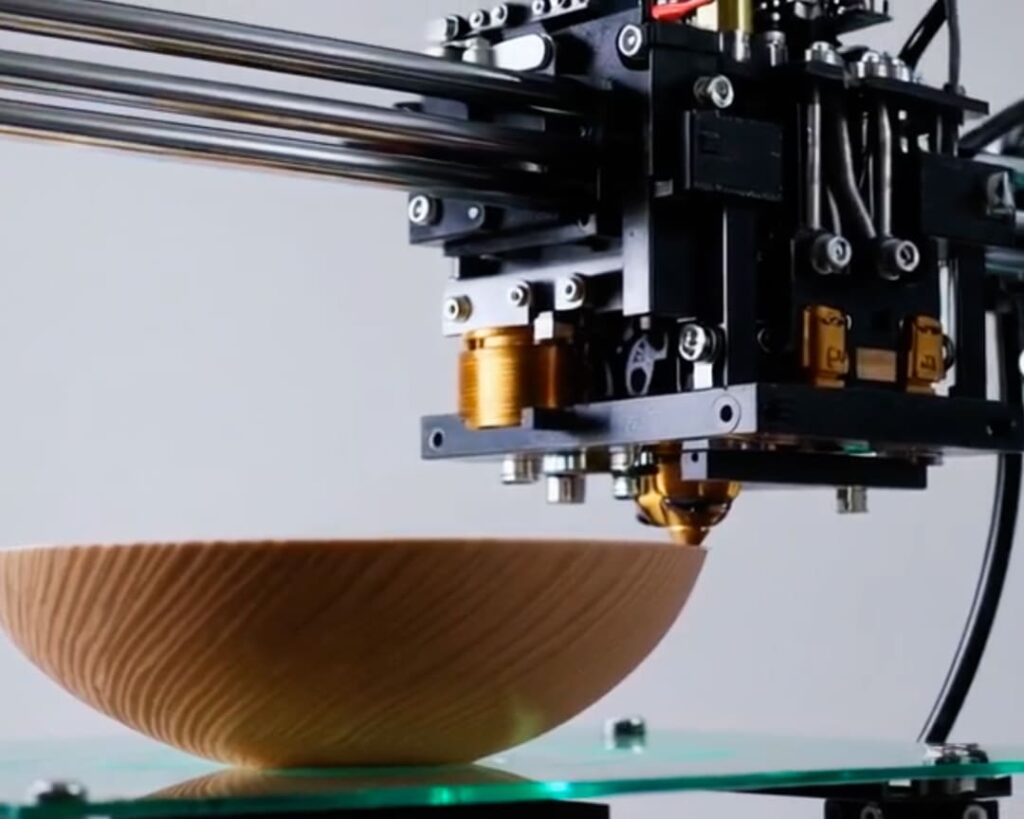

A collaboration project with designer Shogo Okawa, who creates products for everyday use, such as vessels, by shaping plant-derived, renewable resin “PLA” with a 3D printer. The project focuses on developing organic forms of vessels designed for use in various settings. This is not only an experiment in base shaping but also an exploration of new Urushi finishing techniques, where traditional methods are flexibly interpreted to create unique Urushi expressions.

PLA (polylactic acid) is made from plant-derived, renewable resources such as corn and sugarcane. By utilising parts of these plants that are not consumed by humans, it helps reduce waste and minimise rubbish. Furthermore, when buried in soil containing microorganisms, PLA breaks down into carbon dioxide and water through microbial activity. This means that even if there is a failure during the shaping process, disposal is not an issue, as it will naturally return to the earth. In this way, production and disposal can be achieved through carbon-neutral manufacturing.

By combining this plant-derived PLA with Urushi, another natural material, we are enhancing its functionality while also challenging ourselves to create innovative products that incorporate modern technology.

The Story Behind the Project

Urushi and traditional crafts have gradually moved away from modern daily life due to the diversification of lifestyles and values. Some believe that the evolution of technology has led to the decline of traditional cultures. While this may be true to some extent, it is also undeniable that we, living in the present, are sustained and supported by that very technology. Today, these technologies and knowledge are being used to combat global warming and are driving innovation in traditional crafts.

The Urushiware industry is currently facing a critical situation. In 1975, 500 tonnes of Urushi were distributed, but by 2020, this had fallen to less than 30 tonnes. It’s not just the Urushi itself, but also the artisans needed for Urushi crafts—such as brush makers, painters, and charcoal producers—who are aging rapidly, and there is a shortage of successors. Additionally, the decline of woodturners, which are essential for making Urushiware, and the shortage of wood are also serious issues. Together with our partners, we are working on the 「Asagi Wan (bowl) Project」in Kyoto, which aims to train the next generation of woodturners and lacquer artisans. Through this initiative, we are committed to passing on techniques to young people and creating new work opportunities.

Particularly, the woodturners who specialise in making bowl blanks are concentrated in the Yamanaka Onsen area of Ishikawa Prefecture, and in regions like Kyoto and other Urushiware production areas, local production of bowl blanks has become increasingly difficult. As the demand for Urushi decreases, there is a vicious cycle where, even when there is an order for Urushiware or a desire to create products, the necessary base materials—wooden blanks—are not available. This situation can lead to missed business opportunities.

In order to address these issues, we are working on training woodturners through the Asagi Wan Project as a model case. At the same time, we believe that exploring and developing new methods of base shaping using modern technology and new materials is also essential for the future of the Urushiware industry.

Furthermore, expanding internationally is essential for the future growth and sustainability of Urushi demand. PLA resin, due to its resistance to environmental changes such as drying, poses fewer risks of shrinkage or warping, which supports its overseas expansion. While PLA alone may have concerns regarding heat resistance and impact durability, applying Urushi, which is heat-resistant and has a strong coating strength, can mitigate these issues.

The “Urushi × PLA × 3D Printer” project will continue its research while translating the findings into products. Through ongoing updates, we aim to open up new possibilities for the future of Urushi.

Profile

Shogo Okawa

Product Designer & Urushi Artist

Based in Kyoto, Shogo Okawa is captivated by the time that Urushi accumulates and continues to create works that connect the ancient and the future. In addition to traditional techniques, he integrates cutting-edge technologies such as 3D printing to create Urushiware. Drawing inspiration from ancient Bactrian stone and bronze tools from the 1st millennium BCE, he explores unique Urushiware that combines both lightweight and substantial textures. Leveraging his design expertise developed at a major electronics company, he creates works that embody both functional beauty and sculptural elegance. Committed to shaping the future of Urushi, Okawa persistently pursues new possibilities in form and design.