High-Dispersion Urushi – Kōrin

Reasons for Adoption in the Restoration of National Treasures and Important Cultural Properties, and the Performance Supported by Craftsmen

Our company has established its technology to disperse Urushi particles more finely than conventional Urushi, and has developed a highly dispersed Urushi “Korin.” Unlike the high dispersion technology known as the three-roll mill manufacturing method (MR), this manufacturing method is a unique purification method that further increases dispersion, based on the conventional manufacturing method that involves thorough Nayashi and Kurome processes. Due to its excellent weather resistance, it has been used in various national treasures and important cultural properties such as Nikko Toshogu Shrine and Himeji Castle (Higashi no Gate, Musha Window, Hanadori Window), as well as furniture at the Kyoto Guest House (see Photo 1).

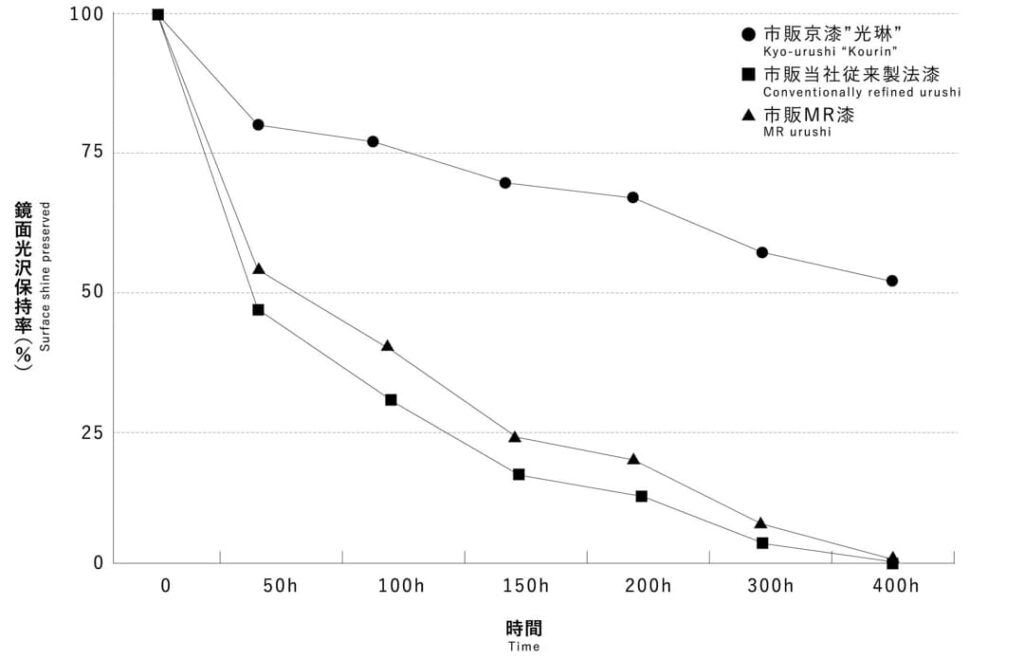

Features 1: Excellent Weather Resistance

The first drawback of Urushi is its deterioration due to ultraviolet rays, rain and wind. It was said that there were problems with weather resistance. However, by highly dispersing the particles, Korin Urushi has succeeded in slowing the initial deterioration significantly more than conventional Urushi, by making the coating film dense and robust. It is currently used in a variety of outdoor buildings, including national treasures and important cultural properties.

Comparison of Changes in Coating Gloss Retention Rates by Accelerated Weather Resistance Tests

Features 2: Excellent Gloss

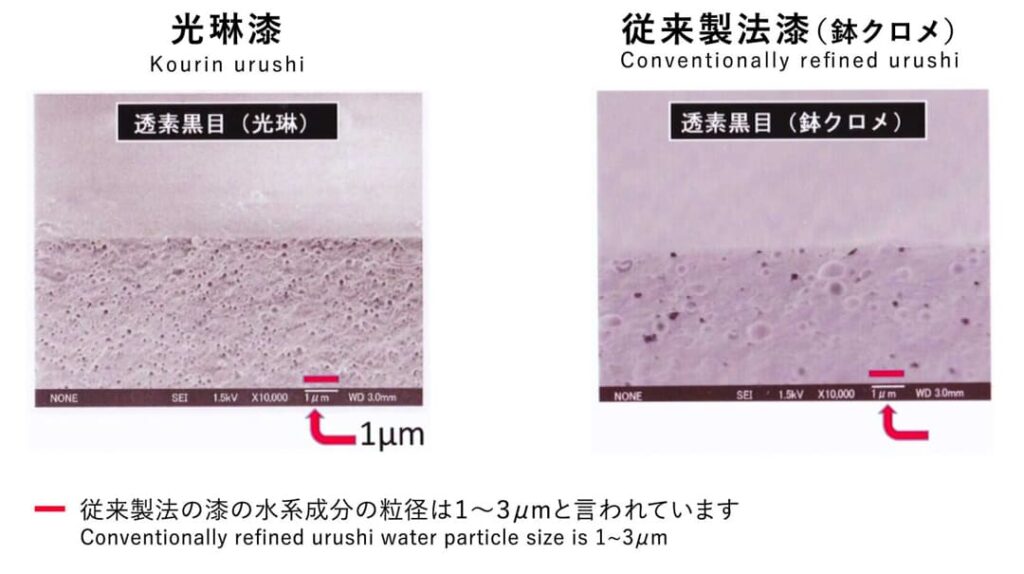

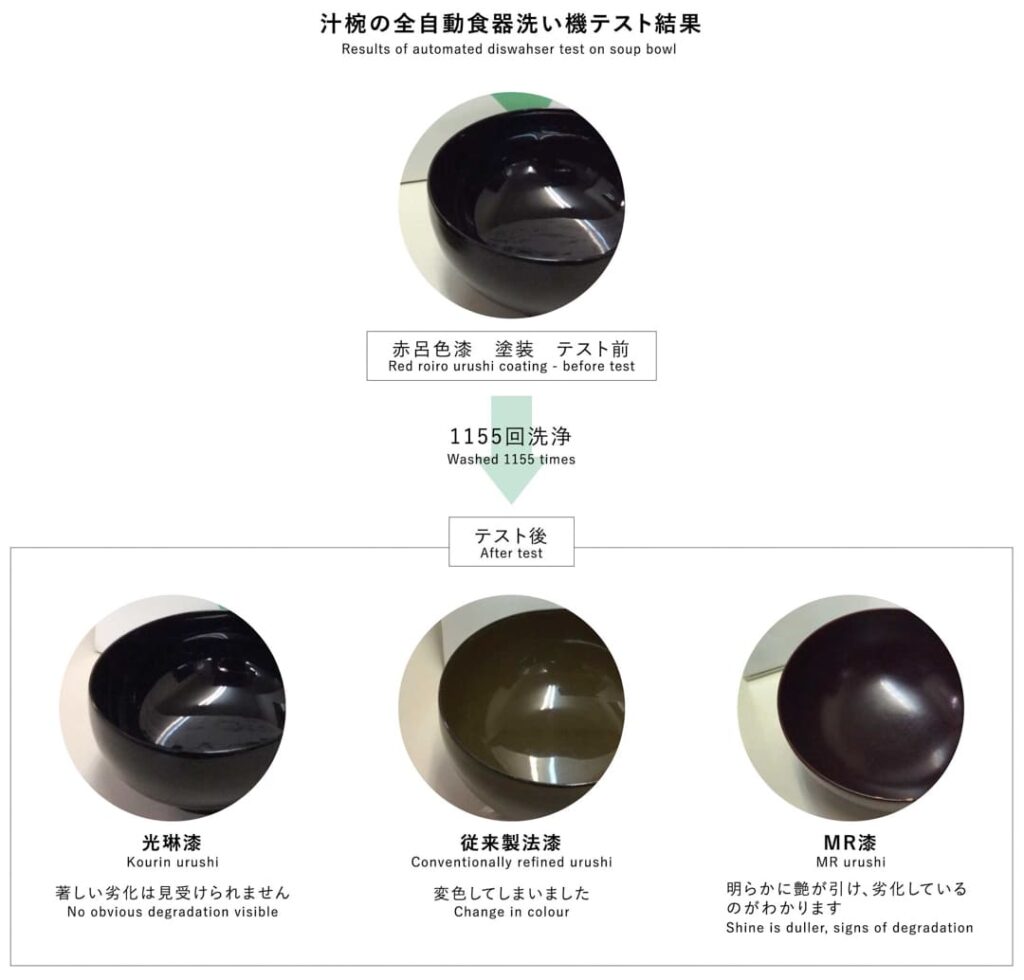

Because the Urushi particles are finely made using high dispersion technology, the coating film becomes smoother, and even if it is oil-free, it can produce a gloss that cannot be achieved with conventional Urushi manufacturing methods (see Figure 1). The conventional oil-free Urushi (Ro-colored Urushi, pure black-coloured Urushi) is only about half-glossy, but Korin’s Ro-colored Urushi is also more glossy and is more glossy when polished with Ro-colored. It is also weather resistant, has a glossy finish even when painted without oil, and there is no need to worry about oil floating over time, making it a lot of use in outdoor buildings such as cultural assets. Of course, oil-coated Urushi is also popular. It also has a good gloss retention rate, and good results have been obtained in dishwasher deterioration tests (see Figure 2).

Conversely, since the luster is increased by finer particles, matte Korin Urushi cannot be achieved based on this logic. Also, if you consider the lustre of oil-free Urushi to be 10, it would be easier to understand if you imagine Korin oil-free Urushi to be around 8, while traditional oil-free Urushi to be around 5. However, please understand that the glossiness may vary slightly depending on the curing conditions, etc.

Comparison with Cross-Sectional Micrographs of Coating Films

Important Note: The dishwasher tests are comparative experiments conducted between Korin Urushi and conventional Urushi. While the results for Korin Urushi are favourable and demonstrate good durability, we do not recommend it as dishwasher safe. For the best care of Urushiware, we strongly advise hand washing and avoiding the use of a dishwasher. This helps preserve the Urushi’s quality, finish, and longevity over time.

Other features

For example 1

The three-roll mill method tends to produce Urushi with low viscosity due to its manufacturing characteristics. However, Korin Urushi undergoes a process of “nayashi” and “chrome,” which allows for viscosity adjustments, making it easier to meet customer requirements, unlike traditional methods.

For example 2

Have you ever experienced the powder peeling off after applying powder Urushi during maki-e (decorative sprinkling of gold or silver powder)? One of the benefits of using Korin’s roiro Urushi is that it ensures proper adhesion and reduces the likelihood of peeling. Additionally, when using Korin Urushi for the surface to be decorated, the core drying is efficient, and the hardness is high, which makes it easier to draw fine lines due to smoother brush movements, as reported by our users.

For example 3

Typically, when polishing roiro (black Urushi), “kami-zuri” or “Ise-haya” is used as the rubbing Urushi. However, Korin Urushi, which allows for adjustment of viscosity and drying time, is also highly regarded as a rubbing Urushi. Using Korin’s fast-drying roiro Urushi (Japanese origin) during the initial or final polishing of roiro Urushi gives a better shine, and in the case of black Urushi coatings, it enhances the black tone and depth. For transparent Urushi or colored Urushi, red roiro Urushi should be used, and for black Urushi, black roiro Urushi should be applied.

Order

Korin lacquer can be selected from the product categories below.