Substitute Needle Charcoal Asakichi Abrasive Stone

Revolutionary Stick Abrasive Stone that Replaces ‘Unbreakable’ and ‘Non-Wearing’ Needle Charcoal

Perfect for Kintsugi, Makie, Raden (Mother-of-Pearl Inlay), and Sculpted Urushi (Carved Urushi) work

In the field of Urushi arts, traditional natural charcoals such as Roiro Charcoal, Suruga Charcoal, and Hōri Charcoal have long been used as polishing materials. While these natural charcoals are still in use today, challenges such as sourcing raw materials, a shortage of skilled craftsmen, and a sharp decline in demand have led to the increasing adoption of alternative Urushi polishing stones. There are various grain sizes available, suitable for tasks ranging from base sanding to Roshoku polishing. In many cases, fine detail polishing might be required. Traditionally, this has been done using charcoal or polishing stones to form ‘needle charcoal’. However, due to the nature of the charcoal and stones, needle charcoal often breaks or wears down quickly, leading to a demand for an Urushi polishing stone that could replace it.

In response to this, we have developed the ‘Asakichi Abrasive Stone’ in collaboration with a polishing stone manufacturer. This new stone employs a completely different manufacturing method from traditional Urushi polishing stones, designed to be thin and long like needle charcoal, yet ‘unbreakable’. Compared to previous stones, it boasts significantly improved durability (‘does not wear out’) and superior polishing power. It is especially well-suited for intricate tasks such as Kintsugi, Carved Urushi, Makie, Raden (Mother-of-Pearl Inlay), and fine detail polishing of corners and carvings. With a variety of sizes available, you can choose the grain size and shape that best suits your needs.

The versatility of the Asakichi Abrasive Stone allows for a wide range of creative applications. It is a convenient tool that addresses specific needs, making fine-detail work much easier. You can further modify the tips for even greater ease of use.”

This translation retains the essence of the original while ensuring it sounds smooth for an English-speaking audience.

Features

Examples of use

Carved Urushi

Asakichi Abrasive Stone is used in an Urushi technique in which multiple layers of paint are carved with a carving knife and the carved surface.

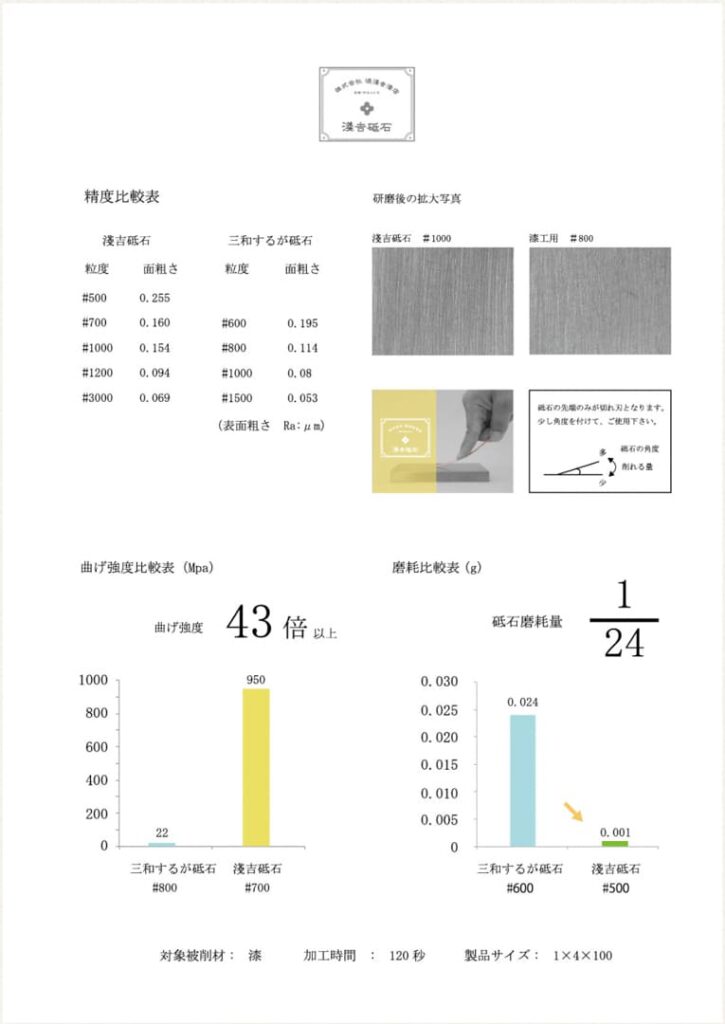

Comparison table of carved Urushi, charcoal, Sanwa Urushi Polishing Stones, crystal whetstone and Asakichi Abrasive Stone in carved Urushi

| Conventional abrasives and granularity | When using Asakichi Abrasive Stone |

|---|---|

| Sanwa Urushi Polishing Stones #600 (Used for forming and using needle charcoal) | #700 |

| Charcoal (Used for forming and using needle charcoal) | #1000 |

| Crystal Whetstone #1000 or #1500 (Used for forming and using needle charcoal) | #1200 |

Kintsugi

| Asakichi Abrasive Stone grain size | Examples of main uses in Kintsugi |

|---|---|

| #180・#250 | Surface conditioning when the Urushi or Mugi Urushi remains stubbornly |

| #360 | #400/500 to prevent sari from falling |

| #400・#500 | Sabi sharpening |

| #700 | Sami finishing sharpening, middle coating sharpening, when the brush markings of painted Urushi are tight |

| #1000・#1200 | Painted Urushi and medium Urushi polishing |

Compared to charcoal, the polishing slurry (研汁) is less likely to turn black, and it is also less likely to leave stains on unglazed items or fine scratches, which is an additional benefit.

Makie and mother-of-pearl

In the case of Takamakie

When raised high, it is useful for polishing the corners of areas that are angled to rise from the flat surface.

Polishing the shell carved part

For example, when carving thick shells to represent the leaf veins, it is necessary to polish the carved part, but I’m sure many people have had trouble polishing these thin parts up until now. Using Asakichi Abrasive Stone is convenient because it can be polished without stress.